|

The Internet's Largest and Fastest Growing Engraving Community

Discuss hand engraving using basic to the most advanced methods and equipment

Forum Members: 14,761. Welcome to our newest member, AnicaLin

EngravingForum.com -

Domain since Feb 7, 2003

Graver Video Conferencing is empty Join now!

Graver Video Conferencing is empty Join now!

|

|||||||

| ENGRAVING TOOLS - Paypal accepted | Classes | Glossary | Feedback | Tips | Sharpening | Bulino | Videos | Forum Policies |

|

|

|

Thread Tools |

|

#1

|

||||

|

||||

|

I've always been a big-vise engraver - that's why my old Ray LaTourneau Block has always occupied Engraving Bench #1.

Sorry old friend, I moved the 45lb LaTourneau to Bench #2 this afternoon shortly after my new 90 pound Lindsay Titan arrived. ![Willy Nilly[1]](/images/smilies/top smiles/willy_nilly[1].gif) This thing is massive, and unpacking and lifting it in place no easy task. It's also smooooooth, and it doesn't move - at all! For all the good things I can say about the LaTourneau, it's biggest downfall is that it still sits on one of those silly rubber tires, and it just feels spongy. I had gotten used to that, and it really didn't occur to me that the new Lindsay Titan would "work" so solidly. Seriously, the graver action is far more effective when the block (no matter what its weight) sits solidly on the bench, and without the rubber tire absorbing some of the impact of the graver strike. This big boy sits on a solid aluminum ring lined with hard leather - the leather provides enough "tac" to keep the ball tightly held in place. The tension between the block and the base is enough enough that it works equally as well with the air graver and the hammer and chisel. I had been working this Python for the past few weeks. When I placed it in the Titan and started to engraved new lines and scrolls I felt the subtle differences in the graver action immediately.  I have some major inlay and sculpting work to do on this gun, and I just know that all that heavy pounding is going to be so much more effective in this block. OK, Steve asked that I post photos of work-in-progression on this Python - so let's walk though the process of inlaying the Colt Onion Dome on the left panel  In this photo I have started preparation by excavating the area of the onion-shaped dome The 24K dome was sawed out and the relieved area is cross cut to raise burrs  Now the area where the columns are placed is excavated and the area is cross-cut with a "Detail" graver  The inlay is sawed from a 20 ga. piece of fine silver and the inlay cavity is burred up  Both pieces of metal are now hammered into place and smoothed  Now I can continue by designing and cutting the scroll work  The scroll work is completed and I'm ready to detail the inlay  The Colt Onion Dome is detailed - I'm ready to go to the opposite side of the gun to create another Colt inlay. Notice too, that this left panel is a "cover plate." That is to say that it is placed into an opening that allows the inner working to be installed. That means that if you are to do a inlaid border (this Python has a double border) you necessarily have to do it in broken sections that align or register properly when the gun is reassembled. Last edited by MikeDubber; 11-20-2016 at 10:03 PM. Reason: Phiotos |

|

#2

|

||||

|

||||

|

Glad it arrived safe, Mike!.. And it is going right to work! As the Python projects moves along if time allows, please post more pictures of the project.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#3

|

||||

|

||||

|

Quote:

Super Mike! Thank you for adding more photos of this Python project! Do you have some custom jaws bolted on to the vise? If so, is it using the large 3/8" bolt holes in the top of the jaws or the 1/4" bolt holes?

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#4

|

||||

|

||||

|

These are the old "Inside Frame Holders" that I use for holding Colt SAA's, Pythons and other such revolvers in the vise jaws. These are held by opening the vise jaws so they squeeze outwardly against the top and bottom of the cylinder opening. I've had them forever - they fit perfectly in the pre-drilled holes of my new Titan.

![Thankyou[1]](/images/smilies/top smiles/thankyou[1].gif) *see the inside holding jigs in the photo.. ...and another thing; I always mark my block jaws with L and R. I take the jaws and lead screw out once a week to clean and remove all the cuttings that fall in the opening. I also sand and file with the parts in the vise and you don't want want hat stuff building up in the works! You'll see my hand engraved L and R on the Titan...and maybe you can also see that the left boss of the lead screw is engraved with a small arrow pointing left. If you do that and you align the block with the manufacturer's marks at the bottom, you can easily reassemble after cleaning without getting the parts mixed up. I calculate that there may be 4 different ways you can align all these parts on reassembly, if one or more of them are placed incorrectly, the block won't work, or the threads work in reverse....I hate that !!

|

|

#5

|

||||

|

||||

|

Cool and thanks again for the good photos the project. Early on with the Goliath's I quit placing a hex hole at both ends of the screw for the reason you're describing. The hex hole was only at one end so that when you opened and closed the vise it would be right hand. I had comments that some wanted the hex hole at both ends so I went back to that. The easy fix and what was done with the early low profile dovetail vise was mark one end red and the other end blue.

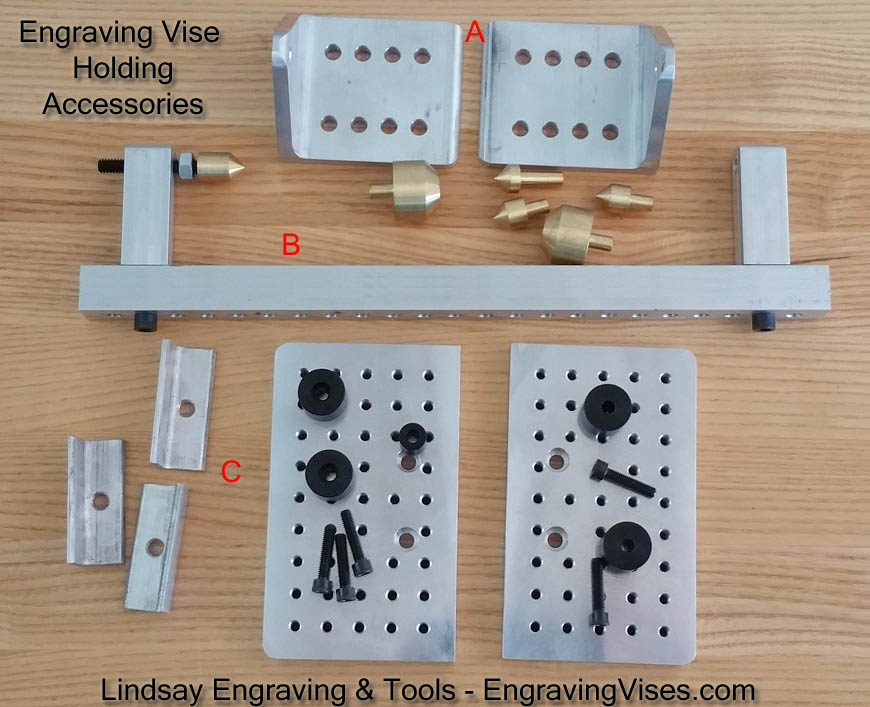

If someone needs a custom jaw attachment out of metal let me know. The wood ones are easier to make up yourself. The below sets are available. They were made for the 30# Goliath and the turntable vise but they will also fit the smaller of the two threaded holes in the 90# Titan.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#6

|

|||

|

|||

|

Beautiful...........just plain Beautiful............

|

|

#7

|

|||

|

|||

|

Great work, as usual, Mike. Your work is inspirational to us newbies. That is a huge vise. I'm going to be buying one of Steve's Goliath vises as soon as he has one that is ready to ship. I'm assuming that as a newbie (just under one year since starting engraving), that a Goliath should serve me well for quite some time?

|

|

#8

|

|||

|

|||

|

Hi

Mike thank you for the work in progress pictures of the python revolver. The pictures were interesting and intuitive. Most Appreciated SE ![Yo[1]](/images/smilies/top smiles/yo[1].gif)

__________________

Learn from those who know more than you do and teach those who know less than you do. - I.M. |

|

#9

|

|||

|

|||

|

Steve is probably already working on a vise big enough for helicopter parts...

![Wink[1]](/images/smilies/top smiles/wink[1].gif) And perhaps an Airgraver big enough to work on stone monuments? Brian |

|

#10

|

||||

|

||||

|

Hi Mark, A guesstimate for when the updated stainless Goliaths are ready is mid to late January.

Quote:

Only under 10' foot high monuments! Only under 10' foot high monuments!

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

#11

|

|||

|

|||

|

What's been updated on the Goliaths?

B. |

|

#12

|

||||

|

||||

|

They will be made from stainless with hardened jaws, pin plates and screw, similar to the Titan. Also the base will be like the Titan's.

__________________

__________________________________ Steve Lindsay AirGraver.com EngravingArtist.com |

|

| Bookmarks |

|

|